Flue gas denitration related substances and chemical names

Release time:

2024-10-14

Nitrogen oxides are one of the main pollutants in air pollution, which has a serious impact on the environment and human health, flue gas denitrification technology is used to reduce nitrogen oxides (NOx) emissions in industrial waste gas environmental treatment technology, in the chemical reaction process, will involve a series of chemical reactions.

Nitrogen oxides are mainly chemical substances composed of nitrogen and oxygen, which occupy an important position in atmospheric chemistry and environmental science. Its main components include: nitric oxide, nitrous oxide, nitrogen dioxide, nitrogen trioxide, nitrogen tetroxide and nitrogen pentoxide.

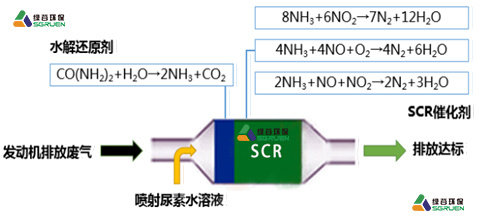

At present, there are two main ways of flue gas denitrification: selective catalytic reduction and non-selective catalytic reduction. The most widely used is selective catalytic reduction (SCR denitration). In this way, in order to control NOx in the exhaust gas of diesel engines, NH₃ or urea (usually a urea solution with a mass ratio of 32.5%) is used as a reducing substance. In ₃ under a certain temperature and under the action of a catalyst, NH₃ reforms NOx into N₂ and H₂ ₃, because NH₃ preferently reduces NOx. Without first reacting with O₂, it is called "selective catalytic reduction".

However, ammonia ₃ is a colorless gas with a strong irritating odor, a kind of inorganic chemicals, with a density of 0.771g/L, a boiling point of -33.5 ° C, a melting point of -77.75 ° C, and a relative density of 0.59. It is highly soluble in water, forming ammonia monohydrate, which is weakly alkaline. In order to avoid secondary pollution caused by NH₃ leakage during the selective catalytic reduction process, we coat a certain proportion of ammonia escape catalyst (ASC) in excess NH₃ at the end of the SCR carrier to ensure that NH₃ reacts with O₂ to form N₂ and H₂O to avoid secondary pollution.

Green Valley Environmental Protection has a unique technical advantage in the field of NOx treatment, and has a large number of successful cases and data accumulation in industrial manufacturing enterprises, power plants, metallurgy, steel, glass, cement and various heat treatment industries. Independent research and development and resource sharing is a team of Green Valley environmental scientists with a global career, with three important capabilities:

1. Independent catalyst development capability. In the case of 350-550℃ diesel exhaust temperature, the treatment efficiency reached more than 98%;

2, accurate control ability. Through a number of world-renowned engine matching practices, high-precision sensors, exclusive electrical design and matching with the world's top electrical components, the precise collaboration ensures that the NOx and NH₃ treatment efficiency in SCR and ASC systems meets the world's most stringent emission standards.

3. Custom development. Green Valley environmental protection database collects the original emissions data of the world's mainstream high-horsepower engines, and many well-known engines have accumulated dozens of MW of different fuels, different scenarios, and successful experience in the treatment of pollutants such as PM, CO and NOx in engine exhaust.

Green Valley Environmental Protection continues to provide customers with stable, reliable, energy-saving and efficient flue gas treatment products and customized overall solutions. We look forward to cooperating with interested parties from all walks of life around the world to jointly promote the road of green development, jointly create green industry-city integration projects, and promote the development of big data and energy conservation and environmental protection industries.

Related news